Con el mundo cambiando día a día, los productos electrónicos de consumo están cambiando continuamente y con eso, hay un aumento en el uso de tecnología avanzada de moldeo por inyección. Este proceso no solo sirve para mejorar la apariencia de los productos, sino que también sirve para mejorar sus aspectos funcionales e incluso de resistencia. A medida que el mercado continúa demandando dispositivos electrónicos de alta calidad, surge la pregunta del papel que tiene el moldeo por inyección avanzado en ellos.

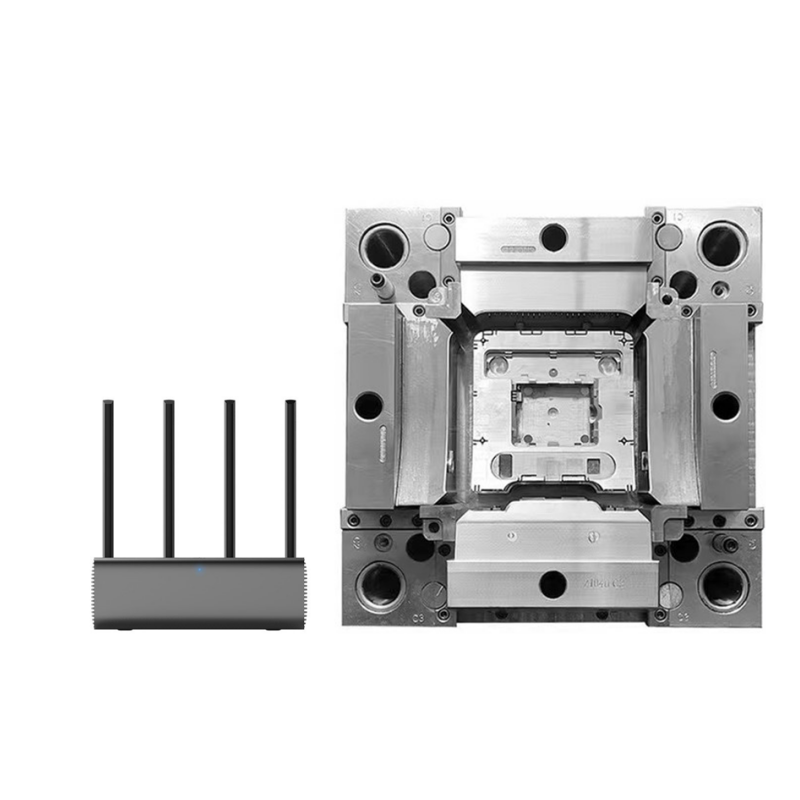

El moldeo por inyección es un proceso que introduce un material fundido en un molde con el propósito de crear obstáculos de formas y diseños complejos. Este método es bastante favorable para la fabricación de componentes electrónicos, ya que los límites de dimensión y tolerancia se pueden controlar bien. Con la tecnología de endurecimiento y los materiales que la hacen posible, permite la producción de componentes ligeros pero robustos con partes complejas que antes eran inalcanzables.

El cambio rápido que la economía global ha estado enfrentando ha llevado a muchas organizaciones a interesarse en la tecnología de inyección avanzada, especialmente por su bajo costo de fabricación. La automatización de las etapas del sistema de fabricación conduce a tasas de producción crecientes, pero los desechos están en niveles diminutos. Esa eficiencia también reduce el costo operativo y disminuye el tiempo de entrega, lo que proporciona una respuesta rápida a las necesidades del mercado en la fabricación. Eso ayuda a las empresas a ser competitivas en una industria en constante cambio y exigente.

Además, gracias a un moldeo por inyección altamente sofisticado, se hace posible la incorporación de características multifuncionales en una sola pieza. Esta capacidad es muy crucial para los dispositivos electrónicos de consumo, ya que el volumen promedio está mayormente confinado. Al permitir que diversas características se proporcionen en una sola pieza, pueden reducir el número de contactos de ensamblaje, así como aumentar la durabilidad de todo el producto. Este avance se traduce en un mayor nivel de satisfacción entre los usuarios y, por lo tanto, los consumidores.

Los dispositivos electrónicos están aumentando en número y, por lo tanto, el tema de la sostenibilidad ha levantado cejas entre los fabricantes. La automatización de las tecnologías de moldeo por inyección parece estar avanzando hacia la tendencia de utilizar materiales reciclables y minimizar la cantidad de energía utilizada. De esta manera, no solo se logran las necesidades legales, sino que también se cubre un mercado con una masa ecológica más grande.

Para concluir, los efectos provocados por el moldeo por inyección avanzado en el caso de los bienes de consumo electrónicos son amplios y variados. Cuanto más se aplica esta tecnología, más evidente es que fomentará una nueva innovación en la estructura y fabricación de productos. Aquellas empresas que aprovechen al máximo estos desarrollos estarán en una mejor posición para hacer frente a un entorno empresarial volátil y, al mismo tiempo, garantizar a los consumidores productos de alta gama y respetuosos con el medio ambiente.

Las tendencias de la industria sugieren que habrá un mayor enfoque en la fabricación inteligente y, en consecuencia, en la automatización en la industria del moldeo por inyección. A medida que más fabricantes implementen la Industria 4.0, la amalgama de tecnologías IoT y AI llevará la producción y la calidad del producto a nuevos horizontes. Estar al día con estas tendencias será de suma importancia para las empresas que pretenden competir en el mercado densamente poblado de bienes de consumo electrónicos.

EN LÍNEA

EN LÍNEA